What are On Location Product Photography Services?

On location product photography services eliminate the logistical complications of physically moving products from your distribution center to a third party studio halfway around the country. Our on location services can be the most efficient and affordable way to capture a high volume of products depending on your specific needs.

There are four basic customer requirements to ensure a successful on location project: 1) square footage, 2) electrical bandwidth, 3) products with the correct data, and 4) support staff to deliver the products to the photography team. The experience will be the same as if the products were photographed in our Chicago studio. As for the shoot, daily product throughput varies significantly and is affected by size, difficulty, and product orientation chosen for the style guide.

In order to create high quality images for e-commerce, the products usually need to be physically in front of a camera. This seems fairly obvious, but in many cases, it’s easier said than done. Pulling product, packing, shipping, unpacking, shooting, repacking, reshipping, receiving, unpacking and restocking all take time and resources. Due diligence has shown that many customers would prefer the studio production come to them as it means saving valuable resource time on their end and products do not have to be taken out of stock.

How Does an On Location Project Work?

Project Planned

After a consultation with our operations team, and the decision has been made that an on location project is the best option, the planning begins. We analyze the product mix, consult with your photography staff (if there is one) and decide on the best course of action. We can bring a fully customized studio to you. Our configurable 360 degree photo sets can be installed in any location. We’ll collaborate with your team to categorize, prepare, and capture products.

Studio Set Up On Location

Setting up an on location studio is somewhat akin to running a military operation. There are several moving parts the team must orchestrate. We bring everything from the obvious photography gear to servers, and prep tables all the way down to garbage cans. Our professional installers coordinate with your building management and shipping teams for a smooth load in and set up. Site visits are a great way to determine the best installation space for optimal product-photography flow, with minimal interruption to your daily operations.

Products Sorted

You’ll be assigned a project manager, who will manage the on location team as well as interface with your staff to ensure that your products and associated data get through the process at a high velocity. The manager will analyze the product mix to create the most efficient product pick order to benefit your team and ours. In addition, we bring in a fully-trained photography team that includes photographers, merch coordinators, and product imaging quality control (QC) staff.

Products Photographed

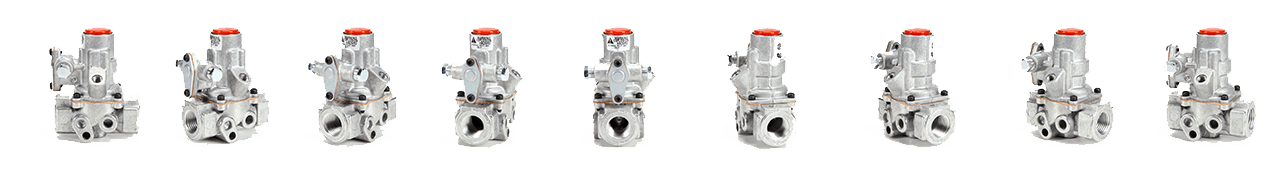

The on location photographers use the same leading 360-degree automated robotics and techniques used in our main Chicago studio to capture the best images of your products. During your project, our team will be in constant contact to align with your goals and provide best-practices to ensure you get the most out of your imagery.

Images Approved

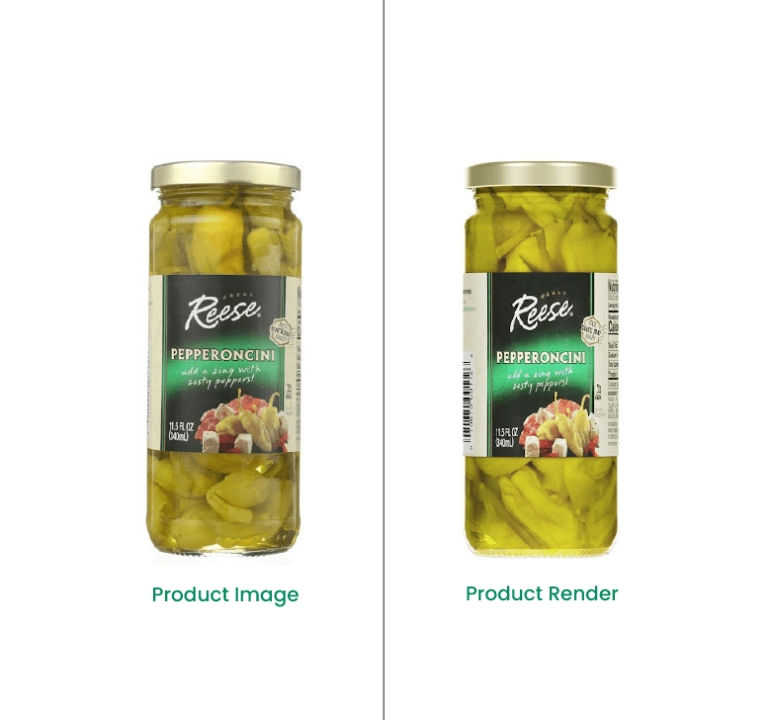

Throughout the project, our QC specialists review your images and provide you with previews for approval. This helps us better understand your needs and give you the confidence that the project is proceeding smoothly. We also offer post-production services, such as image retouching and background removal. While we strive for clean images right out the camera, we understand and are comfortable that some products will need to be adjusted in post production. Once you’ve confirmed the images meet your expectations, we’ll deliver them to you.

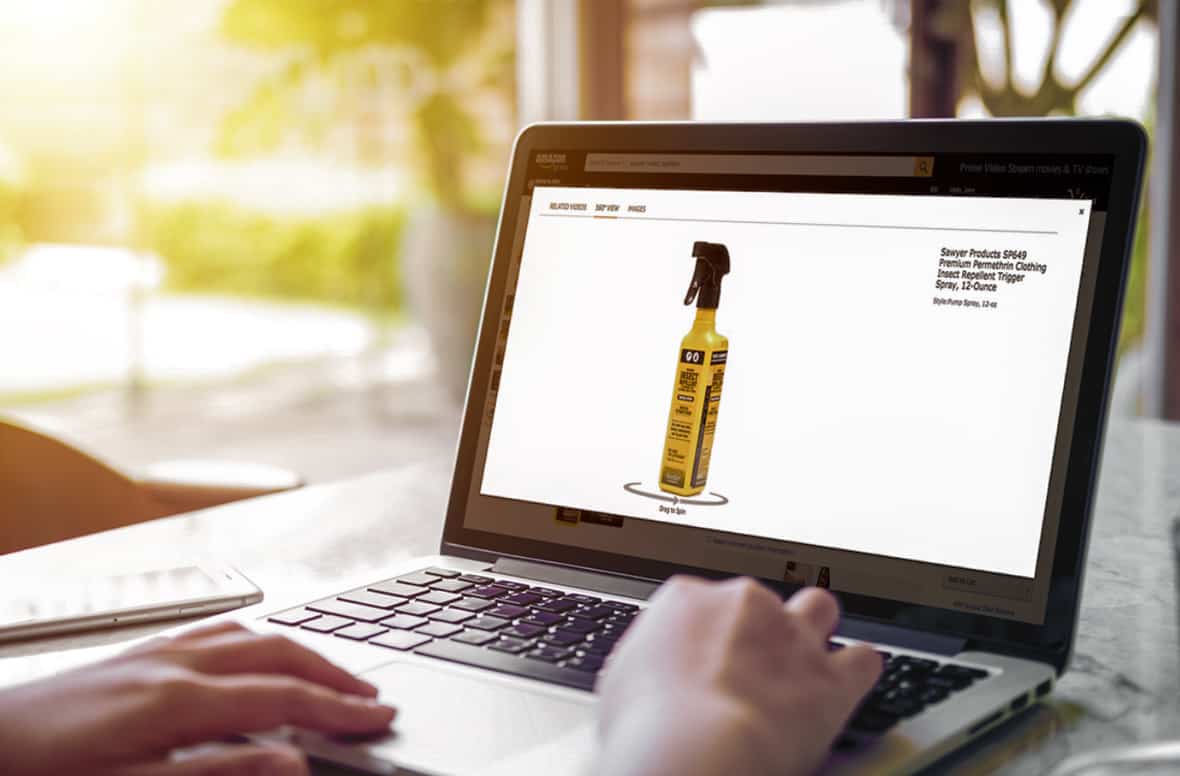

Content Deployed Online

If you’re planning to host spin images on your website, our dedicated tech staff will consult with your team to select the right 360 degree interactive viewer. If you want to send your images to a distributor or retailer, we will export the files with the correct naming conventions and image specs to match your viewer(s) of choice. We can also deliver the files directly to a growing number of e-commerce sites, including Amazon and Walmart.

Large On Location Projects

Heritage Parts

Up until 2016, Heritage Parts relied on a manual process for photographing, cataloging, and then publishing imagery for the thousands of parts it sells online. Not built for high-volume product photography, the process was time-consuming and cumbersome.

To improve both the process pains and the online customer experience, Heritage Parts partnered with 1WorldSync. With its initial 60,000+ parts photographed and uploaded, Heritage Parts has since integrated 1WorldSync’s 360-degree spin equipment into its regular workflow.

Allied Electronics & Automation

With a need to give an engineer the ability to see specific product details, and also striving the be known for best-in-class digital marketing, Allied Electronics & Automation turned to 1WorldSync. Prior to working with 1WorldSync, Allied relied heavily on suppliers to provide imagery but the content lacked consistency.

By partnering with 1WorldSync, Allied is clearly demonstrating its digital technology leadership. With over 20,000 products now spinning online, Allied has started to see increases in conversion rates for products using 360s.

Grainger

Grainger wanted to help its suppliers create scalable product content that would maximize their brand and investment while also creating a better online customer experience. The team turned to 1WorldSync to help them develop and scale best-in-class, interactive 360° product imagery.

With over 130 suppliers selling around 20,000 products online, Grainger has developed an initiative for suppliers to provide 360s in order to improve consistency and sales.

Parts Town

Drawn by the challenge of buyers purchasing the wrong parts, Parts Town knew they had to find a better solution. The team quickly realized that 360-degree imagery was the answer – due to the ability to zoom in and focus on any perspective of a product.

1WorldSync produced 360-degree images for 25,000 products in three months. The team developed the industry’s first mobile app using this product content, called PartSpin. After the initial project, the 1WorldSync team trained the Parts Town photography team to operate the 360-degree robotic equipment for their remaining 40,000 products.

Now that you know more about on-location product photography services, you have a better idea of whether this business model works for you. We’re here to make it easier for your company by providing a more efficient and affordable way to capture a high volume of products, without the logistical hassle.

If you are interested in learning more about our on-location product photography services, get in touch today!